Seeing the Future: Improving Demand Forecasts

- Michael Hunter

- Apr 18, 2024

- 4 min read

Updated: Apr 24, 2024

“Never make predictions, especially about the future.”

-Casey Stengel, New York Yankees Manager, circa 1950s

Ever wonder why retailers run out of stock on some consumer products faster than others? Here we gaze into the crystal ball and explore how to improve forecasting.

What makes forecasting difficult?

Let’s start with the obvious. No one can predict the future.

If you doubt that, look at how even the experts fare. Roughly 80% of sportswriters picked the Kansas City Chiefs to beat the Tampa Bay Buccaneers in the Super Bowl, and a similar proportion picked Gonzaga to beat Baylor in the NCAA final, and none among the dozens polled accurately predicted the outcomes' magnitudes: that the underdogs would win in landslide fashion. In the public health realm, Neil Ferguson – from the Imperial College of London – predicted 65,000 UK deaths from the swine flu, more than 100x the actual number. While the forecast error for hurricane predictions has dropped by roughly 4x since the 1970s, enabling better emergency preparedness, a 10-day forecast is accurate only about 50% of the time.

If experts can’t forecast accurately even a few weeks out, how are companies supposed to do so several months out or longer?

Why is forecasting important?

With the supply chain disruptions and choppy consumer demand amid COVID, forecasting has become more important than ever. Companies forecast because it helps to maximize revenue and profit. It enables more efficient production by telling manufacturing how much product to make, better inventory management by sending proper demand signals on what materials to buy and when, reduced working capital deployment by minimizing cash tied up in excess inventory, and price optimization by reducing sales discounts required to clear out distressed inventory. While improved forecasting won’t solve all problems, it has a clear impact on a company and its earnings.

Here are some of the problems companies face in getting to better forecasts:

Fickle consumers. Even with good research, customers’ actual behavior can vary from their stated or intended behavior. For instance, many consumers will declare a willingness to spend more on a “clean” product but continue to buy the cheaper one with artificial ingredients.

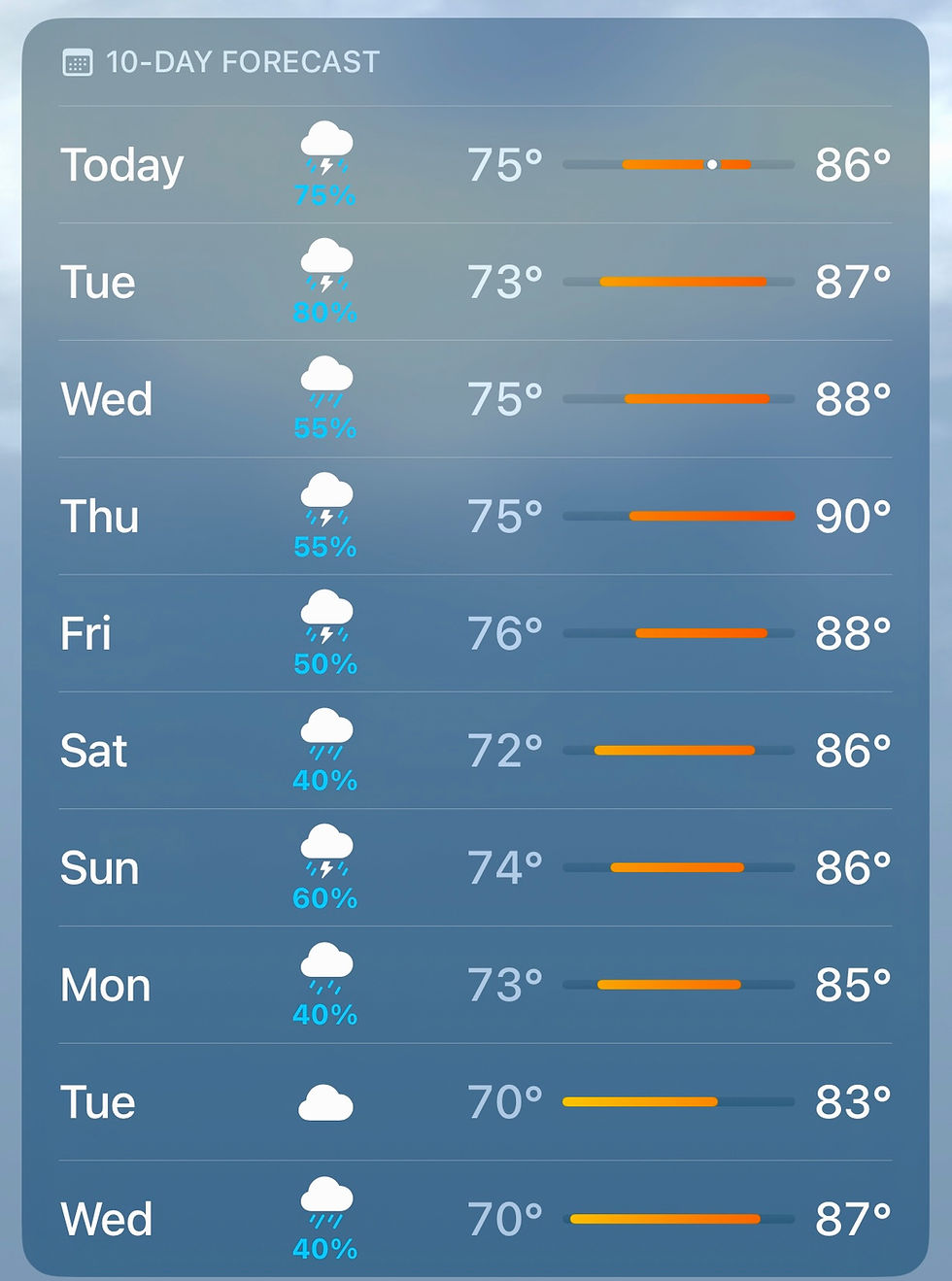

Imperfect information. Retailers can’t always share full information with manufacturers regarding competitive promotion execution, merchandising or store changes, or inventory strategy that will impact both consumption patterns and shipment orders. For example, a manufacturer and retailer can agree to execute a promotion, but the week before a competitor might run a deeper promotion causing consumers to pantry load a substitute product. Also, weather uncertainty can further impact demand for certain categories like snow boots or ice cream.

Under- (or over-) reliance on historical data. While historical data is often the greatest single predictor of current-year volume in aggregate, it is important to adjust a forecast to account for unusual or known-events. For example, stockouts, recalls, customer distribution changes, and competitor product launches need to be accounted for in the current year forecast to predict volume for a product family or new product.

Forecasting at too detailed a level. Companies that forecast consumption or demand at a SKU and customer level a full-year out, miss out on the benefits of variance pooling, in which demand variations across product categories are smoothed out. Forecasting at such a detailed level can create a false sense of precision for managers. The further out the forecast, the higher level the forecast should be.

Two-number systems and forecast accuracy. Many consumer products companies manage forecasts based on their “plan” numbers, even though those numbers are often stretch targets relative to historical patterns. Whether due to innumeracy or simple overexuberance, “hockey stick” plans can wreak havoc on forecast accuracy. Companies should seek to measure and hold accountable those who set the target (e.g., marketing), execute on it (sales), and analyze it (finance), even when it means forecasting a number below the plan.

Recommendations for better forecasts

Here are key questions to consider and accompanying preliminary recommendations:

What factors should we incorporate into forecasting? Utilize macro- and micro-economics to determine which factors correlate with demand for your company’s products, and layer in historical data for applicable categories.

How should we incentivize better forecasting behaviors? Align on a single number across different parts of the organization. Marketing may be incentivized to forecast to the plan number while supply chain, struggling with excess obsolete inventory, should be empowered to push back on unrealistic numbers, with finance and executive management understanding both sides before weighing in.

What tools can help us improve on forecasting? Utilize AI or advanced regression-based models—many of which incorporate POS data, consumer confidence metrics, and even weather patterns—to help reduce human bias and improve accuracy. That said, the person building the model needs to understand the business or be partnered with someone who does so that common sense isn’t lost amid the analytics.

How should we tailor forecasting to our portfolio? Build a process that segments demand forecasts for the products at hand and allows for flexibility. A high-variance product like umbrellas doesn’t require the same safety stock levels, or the same forecast intervals, as a low-variance one like kitchen garbage bags. Historical forecasting can work for stable, high-volume products whereas more complex analytics might be required for new and promotional items.

While no one can predict the future, there are concrete measures companies can take to improve forecast accuracy.

(Article Posted to LinkedIn on August 12, 2021)

.png)

Comments